Automotive OEM Partners with Peak innovations Engineering to Launch New Wheel Designs

ON-SITE TENSION MEASUREMENTS DURING DURABILITY TESTS PROVIDE CONFIDENCE IN THE SUITABILITY AND SAFETY OF NEW WHEELS PRIOR TO RELEASE

CHALLENGE

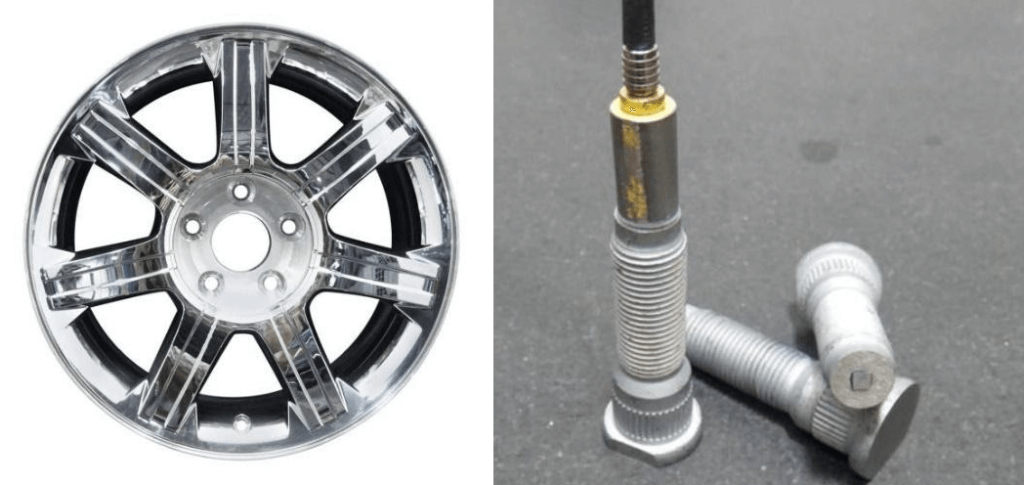

Serving as the connection between a car and the road, the wheel-to-hub joint is arguably one of the most safety-critical in an automobile. Ensuring the joint is designed to achieve and maintain clamp load during operation is of utmost importance. One automotive OEM wanted to quantify this performance to ensure confidence in releasing new vehicle models and associated wheels.

SOLUTION

The OEM partnered with PEAK to develop a tension relaxation test method for the wheel-hub joint. It was proposed to measure tension in the wheel to hub joint on an actual vehicle as it was subjected to use on durability tracks at the OEM’s proving grounds, made possible with ultrasonic tension measurement technology. The OEM provided hubs and wheel studs for PEAK to prepare for ultrasonic tension testing, which included grinding, sensoring, and creating ultrasonic calibration files for the studs and pressing them into the hubs. The prepared hubs were returned to the OEM for fitment on the test vehicle, and PEAK brought portable ultrasonic measurement equipment to the OEM’s proving grounds. Stud tension was recorded after the installation of the new test wheels, and the vehicle was run on courses applying the various loads encountered during service. PEAK used ultrasonic measurements to monitor stud tension throughout the durability tests.

RESULTS

At the conclusion of testing, the tension results were processed by PEAK and a report was sent to the OEM. Based on retained tension criteria, the OEM was able to gain confidence in their design prior to release through quantifiable real-world data. Due to the value-added, PEAK’s contribution to the wheel evaluation process has become a standard operating procedure for the OEM.

PEAK SERVICES PROVIDED

- Ultrasonic bolt tension measurement

- Tension relaxation testing with ultrasonics

- On-site testing

- Test method development

Peak innovations Engineering: For the Ultimate Confidence in Fastening

Company Profile:

Peak Innovations Engineering has a highly technical team to design, test, validate, and enhance the bolted joints within your product application. Joint development and testing are all we do, so we do it better than other available options, both internal and external. Why consume your resources in engineering and problem-solving areas that are secondary to your core responsibilities when we can take care of them quickly, definitively, and cost-effectively? www.pieng.com