Fastener Manufacturer Partners with Peak Innovations Engineering to Develop New Assembly Strategies

CHALLENGE

In an effort to reduce mass and improve engine efficiency, an automotive OEM initiated an innovative project where critical engine fasteners would be downsized while less critical external fasteners would be made of aluminum. In order to generate the clamp loads necessary to keep the critical joints secure, this required an increase in fastener strength up to property class 14.9 in some cases. For both the high strength fasteners and new aluminum fasteners, a reliable assembly strategy was needed to generate the required clamp loads.

SOLUTION

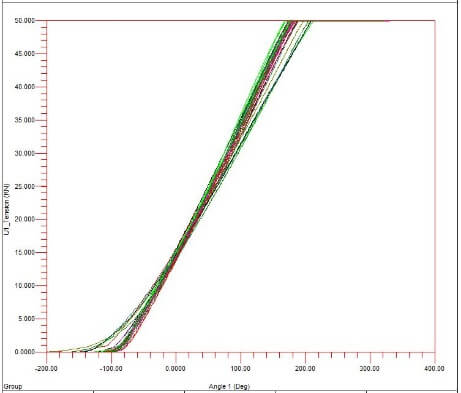

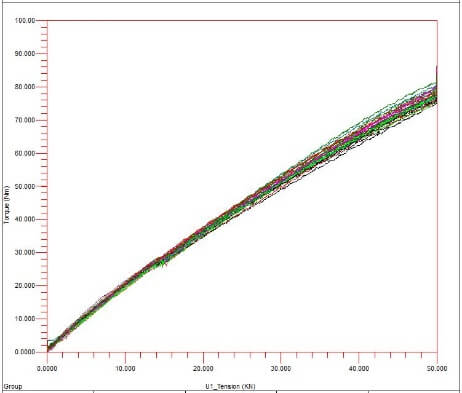

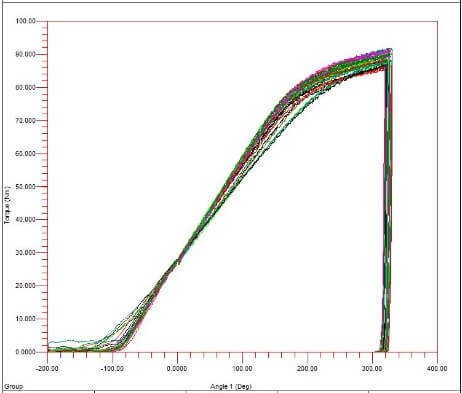

While quite technically competent, the fastener manufacturer did not have the ability to perform the detailed analysis in the timeframe required. Instead, the manufacturer partnered with PEAK innovations Engineering for the evaluation of eight unique joints, including two configurations of connecting rod bolts, head bolts, and main bearing cap bolts. Utilizing in-joint torque-tension measurement with ultrasonics, PEAK used an iterative approach to determine optimum torque only or torque-angle strategies to achieve the desired clamp load for each joint. This included tightening above yield for several of the critical applications. Innovation was required in order to measure tension of several bolts with internal recesses and no back-side fastener access for traditional ultrasonic pickup placement.

RESULTS

At the conclusion of testing, PEAK compiled and analyzed the data and submitted a comprehensive set of data. For each joint an assembly strategy was shown to be capable of consistently achieving the desired tension with the components provided. The project provided confidence for both the fastener manufacturer and OEM that the innovative fastening approaches could be successful in reducing weight while maintaining joint integrity.

PEAK SERVICES PROVIDED

- Ultrasonic Bolt Tension Measurement

- In-joint Torque-Tension Measurement

- Assembly Strategy Development

- Torque-Angle Tightening

PEAK INNOVATIONS ENGINEERING: FOR THE ULTIMATE CONFIDENCE IN FASTENING

Company Profile:

Peak Innovations Engineering has a highly technical team to design, test, validate, and enhance the bolted joints within your product application. Joint development and testing are all we do, so we do it better than other available options, both internal and external. Why consume your resources in engineering and problem-solving areas that are secondary to your core responsibilities when we can take care of them quickly, definitively, and cost-effectively?