PEAK INNOVATIONS ENGINEERING

PEAK INNOVATIONS ENGINEERING HAS THE HIGHLY TECHNICAL TEAM TO DESIGN, TEST, VALIDATE, AND ENHANCE THE BOLTED JOINTS WITHIN YOUR PRODUCT APPLICATION.

Contact PEAK Today:

REASONS FOR TESTING

LOWER ASSEMBLY COSTS

If your products are like most, more than half your direct assembly costs are absorbed by joining and fastening operations. Our team can examine your fastening methods during assembly and make suggestions on improvements to reduce your fastening costs.

PICK THE RIGHT ASSEMBLY PROCESS

Before worrying about the screw boss details, are you sure screws are the best way to design your joint? Let the experts at Peak help you determine the best design..

LET YOUR ENGINEERS IMPROVE REVENUE

Your customers choose your products for their features and overall value. They only notice the joints when they fail. Let your engineers focus on engineering to generate sales, and Peak can make sure your customers will not be disappointed.

LOWER WARRANTY COSTS

Joints are the most common root cause of failure in the vast majority of mechanical systems. Our experts can help you determine joint failure and prevent it so your customers have quality products.

IMPROVE BUILD QUALITY

Do you have persistent build problems with adjustments, alignment, loose screws or ergonomics? These all share a common factor; joint design. Peak is the expert in joint design and testing.

TESTING OVERVIEW

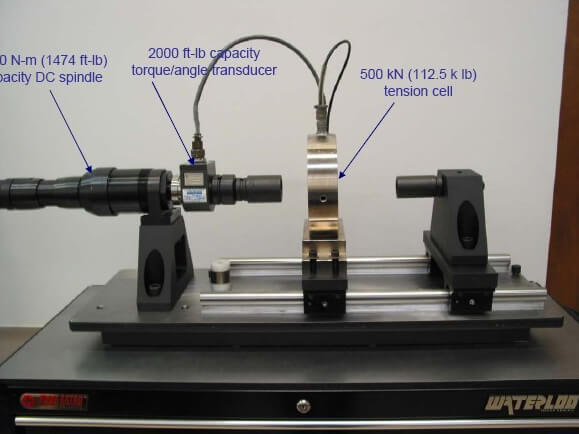

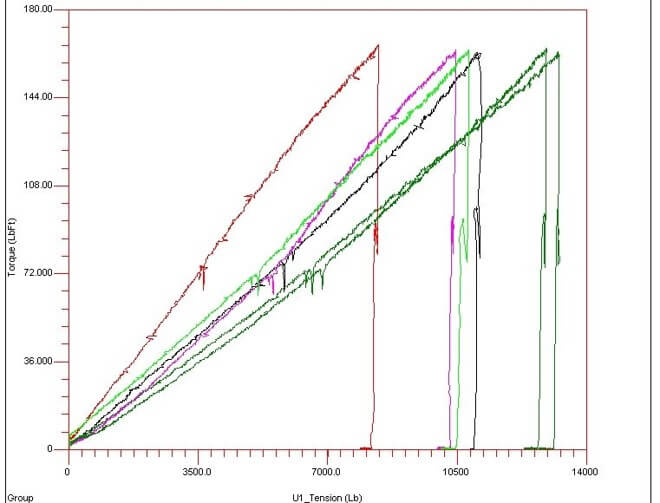

TORQUE TENSION TESTING

Need K factor, nut factor, or coefficient of friction data? Do not guess, contact the experts at Peak for torque-tension testing!

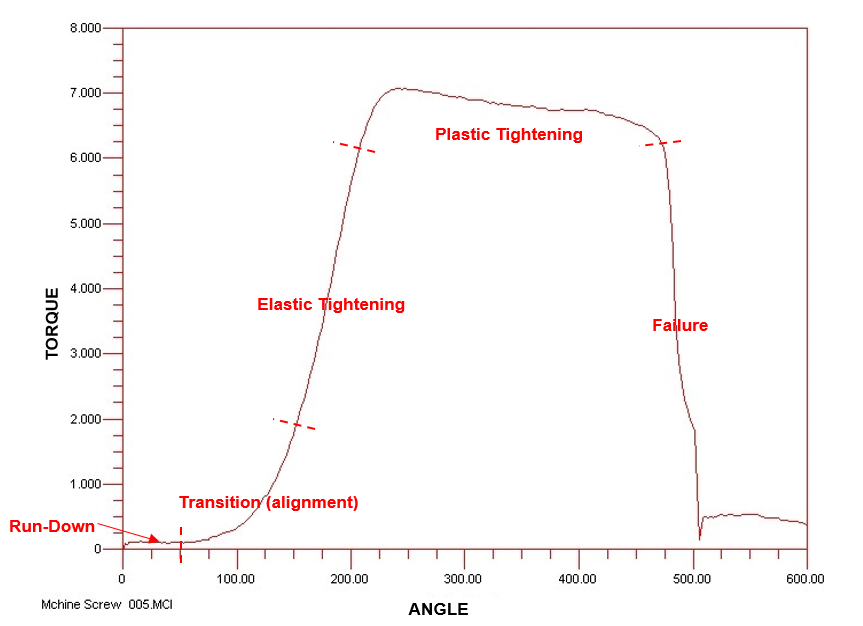

TORQUE-ANGLE TESTING

When fastener tension is not the primary measure of reliability, torque-angle to failure is the most common method of determining installation torque and testing joint capability.

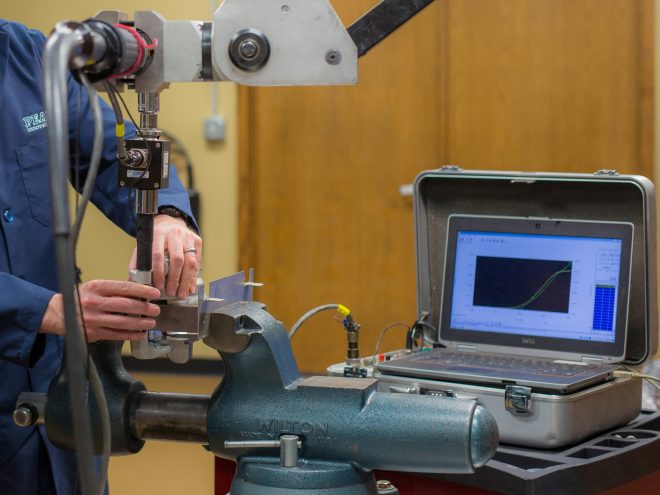

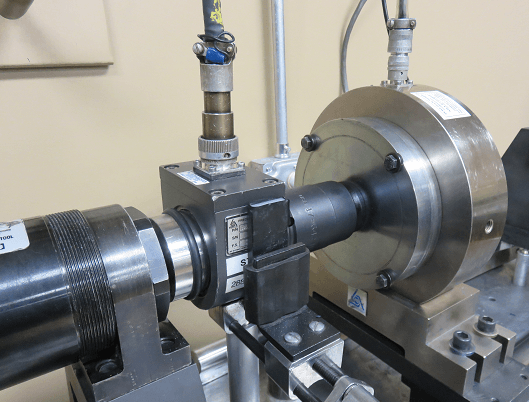

ULTRASONIC TORQUE TENSION TESTING

Whether validating a new design, determining an assembly strategy or diagnosing a problem joint – contact the Peak team to find out how our high-tech methods of ultrasonic bolt testing can be put to use for you.

TESTS COMMONLY PERFORMED BY PEAK INNOVATIONS ENGINEERING

- Establish recommended target torque

- Calculate bolt friction coefficient (K factor)

- Bench top torque-angle-tension testing (with load cell)

- In-joint torque-angle-tension testing (with ultrasonics)

- In-joint torque-angle testing

- Torque-Tension testing

- Torque-angle test

- Torque Study

- Drive-Strip test/study

- Bolted Joint Testing

- Ultrasonic Bolt Tension

- Measure residual torque in assembled joints

- Determine joint rates (hard, soft joint) and presence of component yield

- Determine deflection curves for gaskets or joints.

- Establish bolt tightening strategies and parameters

- Joint slip load or coefficient of friction testing

- Hardness testing

- Ultrasonic Bolt Testing

- Measure and monitor clamp load real-time with ultrasonics

- K Factor testing

- Nut factor testing

- COF Testing

- Torque-angle to failure

- Monitor joint relaxation(temperature/humidity available)

- Troubleshoot inefficiencies or poor yield of production joints

- Fastener selection – head/drive/thread form

- Installation tool accuracy and repeatability

- Competitive benchmarking of fastener use and installation strategy

- ISO 16047

- SAE/USCAR10

- USCAR11

- SAE J174, J174M

- ASTM D5649

- Ford WZ100

- FordWZ101

- GMW14165

- Fastener Testing

WHY OUTSOURCE JOINT TESTING?

Peak innovations Engineering is an ideal choice for joint testing and development. By relieving your engineers of joint testing, they can focus on engineering improvements increasing revenue and sales. Our experience and expertise allows us to optimize joints, propose cost reduction of labor and material and troubleshoot poor yield.

WHY USE PEAK?

Peak innovations Engineering offers independent third-party fastener, joint or equipment testing. Our in-house lab accommodates immediate testing of proposed designs or changes. Peak’s specialized testing can optimize your process parameters including; torque, force, time, etc. Many of our tests can be performed at the customer’s location if requested.

TESTIMONIALS

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. .

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. .

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. .