Bolted Joint Analysis to Diagnose and Eliminate Loosening of a Critical Application

PEAK INNOVATIONS ENGINEERING ASSISTS AN ON-HIGHWAY OEM TO ELIMINATE A FIELD QUALITY ISSUE THROUGH TORQUE-ANGLE-TENSION TESTING WITH ULTRASONICS

CHALLENGE

A specialty vehicle manufacturer (OEM) was receiving reports from field service technicians that the fasteners connecting the vehicle body to the frame were loosening, in some cases resulting in fatigue failures. PEAK innovations Engineering was contracted to diagnose the cause of the loosening issue and suggest potential solutions.

SOLUTION

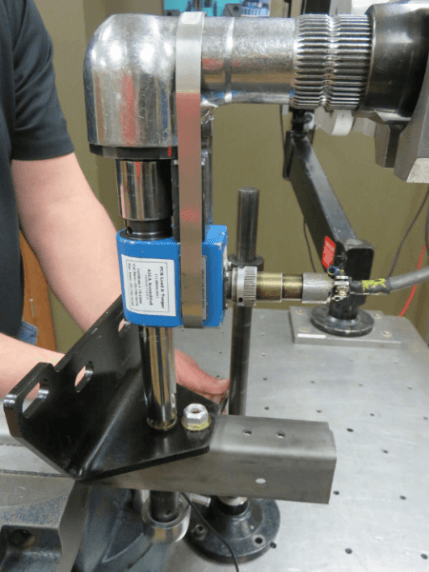

Joint loosening can have many causes, two common causes being insufficient clamp load at assembly and relaxation of components within the joint stack up. PEAK recommended in-joint torque-angle-tension testing with ultrasonics in order to understand the true performance of all components in the joint. The OEM provided test joint sections and fasteners for PEAK to prepare for ultrasonic testing, which included grinding, sensoring, and creating ultrasonic calibration files. The prepared fasteners were tightened to failure while recording torque and ultrasonic tension to gather joint information.

RESULTS

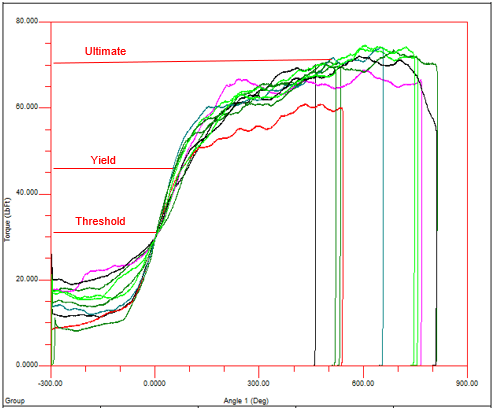

When looking at torque alone, the OEM’s assembly torque appeared appropriate. The nominal torque was above the joint threshold point where all components are pulled together and below the yield point where a joint component begins to plastically deform. However, analysis of the tension data showed that yield was occurring at only 70 to 80% of the proof load of the fasteners – meaning other components in the joint were limiting factors. A review of the tested parts showed the yielding of washers and frame and bracket surfaces.

In order to eliminate loosening, joint improvements were needed to allow for increased clamp load and reduced potential for component relaxation. With test data and analysis of actual joint components, PEAK was able to recommend multiple options to eliminate future loosening issues such as the use of flange hardware and thick washers to prevent the deformation observed. These insights would not have been available through other test methods such as simple torque to failure testing or measuring the torque-tension relationship with load cells. Armed with recommendations based on test data, the OEM was provided with the needed confidence to implement solutions to their loosening issue.

PEAK SERVICES PROVIDED

- Torque-Angle-Tension to failure

- In-joint bolt tension measurement with ultrasonics

- Test method development

- In-house machining

Peak innovations Engineering: For the Ultimate Confidence in Fastening

Company Profile:

Peak Innovations Engineering has a highly technical team to design, test, validate, and enhance the bolted joints within your product application. Joint development and testing are all we do, so we do it better than other available options, both internal and external. Why consume your resources in engineering and problem-solving areas that are secondary to your core responsibilities when we can take care of them quickly, definitively, and cost-effectively? www.pieng.com