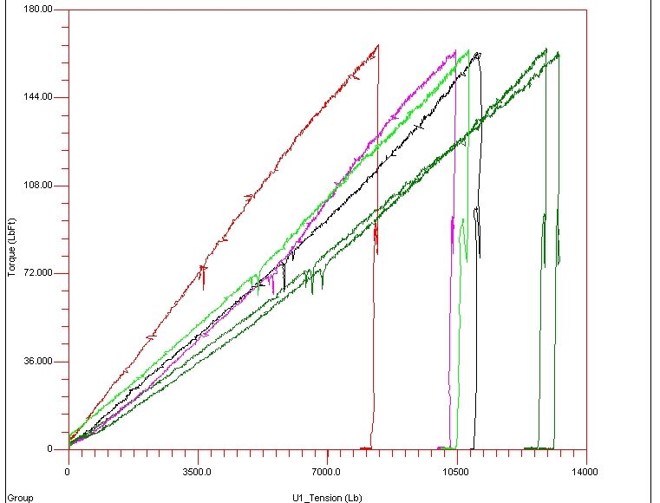

ULTRASONIC TORQUE-TENSION TESTING

Perhaps the most critical element of success in bolted joint design is recognizing the limitations of using torque as an indication of a reliable joint. In most cases, particularly in structural joints where tension should be evaluated, torque is simply easier to measure. Peak innovations Engineering solves this dilemma with our ultrasonic torque-tension testing services. Whether you need ultrasonic preload measurement, or residual tension measurement, we have you covered.

Ultrasonic Bolt Tension Measurement

We use the latest generation of ultrasonic sensor technology that includes bonded sensors which allow us to measure real-time bolt tension of the production bolts in your assembly. By establishing a fixed acoustic path between the sensor and the fastener there is no measurement variation due to coupling between the sensor and bolt.

A significant advantage of using ultrasonics for bolt tension measurement is that it is the only measurement method that does not require any functional changes to the joint or the fastener. Therefore, there is no risk of the measurement method altering the test results. Ultrasonic technology also allows long-term monitoring of joint tension to assess stability in use or after dynamic testing.

Get Ultrasonic Bolt Tension Measurement and Testing

Whether validating a new design, determining an assembly strategy, or diagnosing a problem joint, contact our team at Peak to find out how our methods of ultrasonic fastener testing can be put to use for you. Call us today at 815-847-7722 or use our contact form to leave us a message.

Related Case Study:

AUTOMOTIVE OEM PARTNERS WITH PEAK INNOVATIONS ENGINEERING TO LAUNCH NEW WHEEL DESIGNS

BOLTED JOINT ANALYSIS TO DIAGNOSE AND ELIMINATE LOOSENING OF A CRITICAL APPLICATION