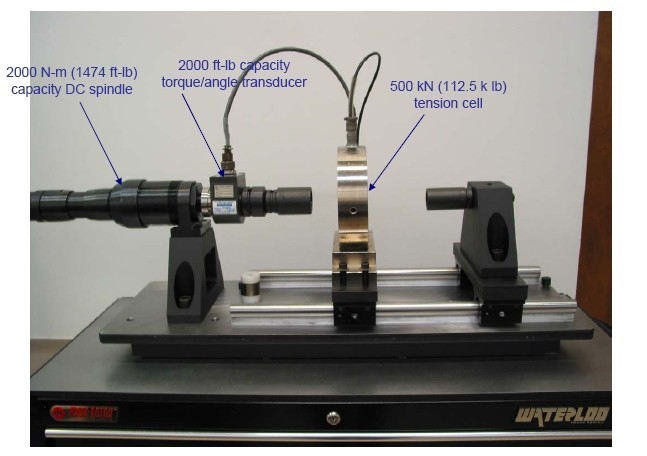

TORQUE TENSION TESTING

Through the use of transducers and load cells specifically designed for fastener testing, the relationship between input torque and induced tension can be determined. The Nut Factor (also sometimes referred to as K factor, torque coefficient, or friction factor) or the coefficient of friction (µ or COF) is calculated from the results of this testing. At Peak innovations Engineering, we have the equipment and expertise to accurately determine COF and nut factor K values.

Purpose of the Torque-Tension Test

This test is commonly used to evaluate the effect of alternative fastener finishes and lubricants or to test the impact of re-sourcing fasteners. By controlling bearing materials, it is also used as a substitute for in-joint torque-tension tests in which fastener access, joint configuration, or part availability prevent the use of ultrasonic testing.

Coefficient of Friction and Nut Factor K Values

In fasteners, the coefficient of friction is a product of coatings and engagement materials, independent from fastener geometry. The nut factor is an empirical value derived from the linear relationship between torque and tension, and takes into account all variables including friction and geometry.

Although a quick Internet search will provide K factors and coefficients of friction for many common fastener finishes, each of these values can vary significantly and is best derived through testing. Our team members at Peak are experts in the torque-tension testing techniques required to derive these values, including the ISO 16047 test specification.

Get Torque-Tension Testing

Are you in need of bolt K factor, nut factor, or coefficient of friction data? Do not guess at these values. Contact the experts at Peak for torque-tension testing! Give us a call today at 815-847-7722 or send us a message through our contact form.

Related Case Study:

PRODUCTION LINE-DOWN SITUATION PREVENTED BY VALIDATING ALTERNATIVE WHEEL NUT