TORQUE-ANGLE TESTING

While measuring tension is often invaluable, there are cases such as non-structural joints, or those with thermoplastic joint members, where fastener elongation is negligible or not the primary measure of reliability. For these joints and structural joints where tension measurement is impractical, torque-angle to failure is the most common method of determining installation torque and testing joint capability. At Peak innovations Engineering, we are your source for accurate torque-angle testing to validate assembly torque specifications, measure residual torque, or identify failure points of an assembly.

The Torque-Angle to Failure Test

In a torque-angle to failure test, the objective is to assess joint performance by utilizing production components. This type of torque study is accomplished by performing multiple rundowns, graphing angle of rotation vs. torque, and tightening the fastener until joint failure occurs.

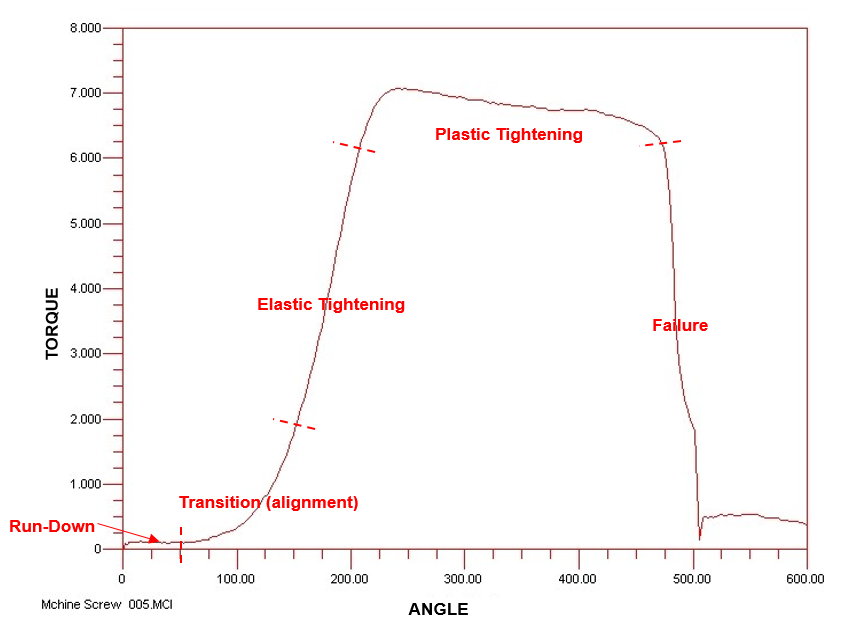

The typical torque-angle trace is shown below with key segments annotated. The rundown captures any prevailing torque generated through thread forming or locking features prior to the fastener seating and beginning to create clamp. In the transition, joint components are pulled together as clamps begin to build until components are fully aligned, and the onset of elastic tightening is achieved. A yield point signifies the upper limit of the elastic tightening range, above which some element of the joint has begun to plastically deform. Continued tightening leads to joint failure, which could be due to the fastener or joint components.

[Graph of angle vs. torque here]

Typically, installation torque is established within the elastic tightening region, with proper consideration given to variability between rundowns and assembly tool capability. It should also be noted that the torque-angle trace is not a foolproof indicator of joint stiffness, as friction variation during the rundown can also cause changes in the linearity of a torque-angle trace. If you need tension data as well, learn more about our bench-top or ultrasonic torque tension testing capabilities.

Get Torque Angle Testing

Whether you need a torque study performed on a machine screw or a structural bolt, our team is here to provide the torque testing you need. For more information about our fastener testing services, call us today at 815-847-7722 or reach us through our contact form.

Related Case Study:

PEAK TESTING HELPED FASTENER DISTRIBUTOR SAVE CUSTOMER $24,950